It can be tricky to get everything to work out just right for an optimal corn silage harvest. The weather, combined with the custom harvester’s schedule and corn silage moisture, are just a few of the details that make harvest a challenge.

Let’s review the basics to help increase your chances of an optimal silage harvest this year:

- Harvest when whole-plant moisture is between 65% and 70%.

- Moisture can drop by as much as .5% – 1%/day.

- To check moisture, replicate in different areas of a field. I always add 1 to 2 points to the moisture check result as there can be a lot of field variability.

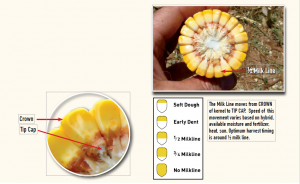

- Half milk line is the rule of thumb, but it’s best to test to verify.

- Some growers increase chopper height to increase grain portion. This makes corn silage drier, so they can start earlier. They also do this to increase fiber digestibility. As the height increases, the neutral detergent fiber (NDF) portion is less and digestibility typically improves.

- Whole-plant moisture of 68% to 70% is the best moisture zone for packing silage in a bunk.

- Although it varies by silo type, whole-plant moisture of 65% is preferred to reduce seepage potential when storing silage in an upright silo.

- As a review, corn silage dry matter (DM) is typically 50% grain to 50% stover. The portion of corn silage that has the most impact on whole-plant moisture is the starch accumulation. Starch dries the mix down. As the milk line drops and more starch accumulates, the lower the moisture.

- Moisture changes can certainly vary based on environment. If we get a very sunny, hot, windy, low humidity day in September, whole-plant moisture can easily drop by 1%.