Tune in for an update from our Agronomy Specialist, Phil Long, on Latham’s Precision Ag Platform. He shares tips and pointers that farmers can implement in the field starting this harvest!

Tune in for an update from our Agronomy Specialist, Phil Long, on Latham’s Precision Ag Platform. He shares tips and pointers that farmers can implement in the field starting this harvest!

By: Phil Long, Agronomy Specialist

Let’s start by examining the process a yield monitor performs to capture yield information while the combine moves

through a field. The GPS receiver on top of the cab pinpoints where each piece of data is coming from; that location data goes to the monitor in your combine to integrate the location with information coming from sensors in the combine. Without correct communication between the receiver and monitor, you cannot record a yield map.

One of the two main sensors recording data is a moisture sensor, which is typically located in or on the side of the clean grain elevator or in the grain tank. The other main sensor is the mass flow sensor, which is typically located at the top of the clean grain elevator. This sensor translates the impact of the grain into an electrical impulse and uses the moisture to correlate a yield value to that sample of grain.

Systems installed on modern combines can be very accurate if properly calibrated. Calibration procedures usually require a series of loads (at least 3,000 pounds) to be run through the combine to provide the mass flow sensor with calibration standards. These calibration loads should be different amounts, and at different flow rates or combine speeds, to make sure the mass flow sensor can adjust to different yield conditions. The moisture sensor also should be calibrated; it’s important to calibrate it against an accurate tester.

There are several other important settings that should be checked before harvest starts: header height stops; flow delay settings; swath width and initial vibration settings for the mass flow sensor. Also be sure field names are in the monitor. This is not an exhaustive list, but it’s meant to serve as a reminder of what to check before harvest begins.

Major yield map issues that may be fixed before or during harvest are setting the correct flow delays and swath widths. If you are not harvesting with a full header because you are not using assisted steering, then bump your width down by a foot or two; that will make your yield calculation more accurate. Setting the flow delay for how long it takes the crop to begin hitting that mass flow sensor from the time your header is lowered will positively impact data quality. (See image.)

Pre-harvest is the best time to look at your yield monitor and settings. Help farmers you work with to calibrate during harvest, so they have quality data to use when making post-harvest decisions.

Written by: Phil Long

Most U.S. farmers use some form of precision ag technology, and the majority of these farmers are looking for ways to use their data more efficiently. Organizing data and offering suggestions on how farmers can increase yield on a field-by-field basis is where Seed-2-Soil® services comes into play.

Technology in the tractor is one part of precision ag. Data that is recorded by the combine, planter or sprayer monitor requires another level of understanding. Here at Latham Hi‑Tech Seeds, we’re working to help farmers find the intersection between crop production and precision ag.

We believe this technology is a huge stepping stone in terms of efficiency and reaching that next level of production on your fields. Understanding the variability on each of your farms is Step One.

Our FieldXFieldSM process focuses on placing hybrids/varieties according to yield-limiting factors combined with data from your yield monitor. We can define smaller “management or productivity zones” that will allow you to put Variable Rate (VR) technology to use on your farm.

Combining data such as soil samples, satellite or drone imagery, disease and insect scouting reports, and planter and sprayer applications gives you a much clearer picture of each field. Armed with this additional data, you can monitor and manage that field throughout the season.

There are many ways to incorporate precision ag technology on your farm. While not everyone will have every technology, using a few tools provides valuable information. For example, variable rate (VR) hybrid planting can provide a $20/acre benefit. We’re testing this technology on a farm in Northwest Iowa and are eager to see the results this fall.

Although most farmers don’t yet have the capability for VR hybrid planting, many have the ability to apply VR fertilizers. Studies show a $5-8/acre benefit from decreasing overapplication and underapplication to areas within a field. If your fields have a large amount of variability, you may reap even more revenue from VR technologies.

Variable rate seeding and applications are just one piece of the precision ag pie. We can work with you to make your data work for you and your operation. It’s our goal to work with farmers and add value regardless of where they are along the technology adoption spectrum.

One simple, but especially important detail, is naming your fields consistently from year to year. Also make sure your monitors and GPS receivers are communicating with one other. You may see a yield number on your monitor, but that doesn’t mean the GPS location and other information is running through your combine. The data coming out is only as good as the information going in! Calibration is key to getting useful results.

I’m looking forward to working with Latham dealers and customers to help bring more value from the combined use of seed and precision ag technologies. Feel free to contact me at 1.877.GO.LATHAM (1.877.465.2842) if you’d like to visit about how precision ag can benefit your operation!

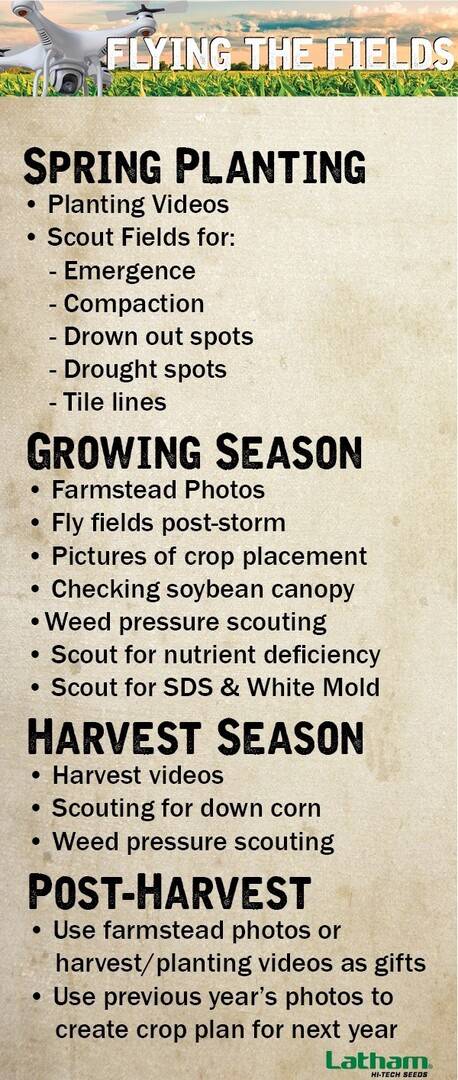

Tune into week 4 of our Ask the Agronomist Podcast! Today we have a special guest who explains how to put your drone photos to work for you. Link on the link below to listen.

Tune into week 4 of our Ask the Agronomist Podcast! Today we have a special guest who explains how to put your drone photos to work for you. Link on the link below to listen.

Ask the Agronomist Podcast Week 4

0:40 – What is HTS Ag?

1:13 – Where do drones fit into the market?

2:18 – What is Drone Deploy?

3:30 – How does a flight plan work?

4:45 – Is there special equipment or camera needed to use HTS Ag’s software?

6:45 – What is the resolution of photos produced?

Remember to submit your questions to us on social media! Find us on Facebook, Twitter or Instagram. Thanks for tuning in!

Only so much preparation can be done in the shop. Take the time to get out of the cab — or have someone else help — to check row spacing and planting depth. Observations and planter adjustments are key to successful emergence scores.

It doesn’t pay to have your equipment in top working condition if you don’t wait for fit planting conditions. Missing the optimum planting window may have a 2-5% impact on final yield but an uneven emergence could cause 5-9% yield loss! Plant according to soil and weather conditions rather than by the calendar.

Our Product Team spends countless hours in research plots and in our customers’ fields, taking field notes. Our mutual goal is to help you maximize yield potential by placing the right Latham® product in the right field. FieldXField™ yields!

Keep these three key areas in mind as you prepare your planter for spring:

Be sure the opening wheels have a serviceable diameter and proper spacing, so the blades have a contact area of 1˝ to 2˝. If they are too wide, you will get more of a “W” in the seed trench, which affects planting depth. If there is too much pressure, discs will wear prematurely.

Gauge wheels and arms should be adjusted to just touch the side of the seed disc. Keep mud and debris from building up on the seed disc as it affects planting depth. Also ensure the closing wheels run true, so the trench closes over the seed.

After wanting a drone for years, Kody Trampel recently purchased a new DGI Phantom 4.

Billed as the “smartest flying camera,” the Phantom 4 has five cameras for improved stabilization and obstacle avoidance. This is an attractive feature for new pilots worried about crashing on their first drone flight, plus it’s advantageous when shooting tight close-up shots.

“Since I’m a rookie pilot, I chose the Phantom 4 because it has sensors on all four propellers,” says Kody, an  agronomy specialist with MaxYield Seed. “This drone will sense an object in its flight path, ascend and fly over it, and then return to its original route. They made it virtually dummy-proof and that’s good for new pilots like me!”

agronomy specialist with MaxYield Seed. “This drone will sense an object in its flight path, ascend and fly over it, and then return to its original route. They made it virtually dummy-proof and that’s good for new pilots like me!”

Another advantage of the Phantom 4 is that you get 25 percent more flight time due to extended battery life.

“I decided to bite the bullet and purchase a drone because I think this drone will give me a competitive edge,” says Kody. “I also think it will make crop scouting a lot more fun. No one really wants to walk deep into a tasseled field of corn when the thermometer reads 90 degrees. Now with the drone, we can scout a 160 acres in a matter of minutes.”

Kody believes the drone’s eye view will enhance, not replace, physically scouting fields. He plans to take photos and then return to his office where he can study those images in detail. If he pinpoints a problem area, he can then return to a particular part of a field where he can focus his scouting efforts.

Kody believes the drone’s eye view will enhance, not replace, physically scouting fields. He plans to take photos and then return to his office where he can study those images in detail. If he pinpoints a problem area, he can then return to a particular part of a field where he can focus his scouting efforts.

Because his drone arrived during #harvest16, Kody’s thoughts were focused on how the Phantom 4 might help him and his farmer-customers develop harvest plans.

“Harvestability can be an issue,” says Kody. “We can keep an eye on the fields all season long and constantly monitor standability and stalk condition. I’ll be able to help my customers prioritize fields for harvest. If I see a field that looks suspect from the air, I can then walk into it and do a pinch test. I’ll also be able to take crop notes. For example, I might notice that one particular hybrid number is prone to dying back or doesn’t have good late-season intactness. That will not only help my customers develop harvest plans but it could help them with seed selection and/or product placement in future years.”

Technology is always evolving, so it’s important to research the available products before making a purchase. Kody purchased his drone from a local dealer, who will be available to answer follow-up questions and to provide maintenance and service. The salesman was able to talk with Kody about the pros and cons of different models.

It’s also helpful to talk with others who have experience using drones. Here are links to other Latham® dealers and sales managers who have been featured in our 8-week “Flying the Field” series:

With nearly four years of flying under his belt, Titan Immel with Upper Edge Ag sees the importance of agricultural technology and puts it to use for his operation and his customers. Titan started selling seed when he was 17-years-old and flying a drone at age 18.

With nearly four years of flying under his belt, Titan Immel with Upper Edge Ag sees the importance of agricultural technology and puts it to use for his operation and his customers. Titan started selling seed when he was 17-years-old and flying a drone at age 18.

“There have been a few major changes since I started flying a drone,” said Titan. “Aside from them becoming a lot cheaper, they have also become more user-friendly.”

Titan has taken drone flying one step further, optimizing its capabilities to enhance his occupation on and off of the farm. He has learned to write prescription maps from his drone, which play a key role in finding every farm’s “sweet spot.” Titan acquires satellite images and takes photos from his drone to write variable rate scripts, which helps him pin point which areas he needs to adjust inputs to get the most out of his operation and customers’ fields.

He replicates these practices for his customers, too. Titan helps farmers see how to delegate inputs across their fields, resulting in the highest yield possible for his customers.

“I chose to purchase a drone shortly after beginning my dealership because I wanted to be there for my customers,” said Titan. “I want to help farmers become more profitable by choosing the appropriate inputs for each unique situation.”

“I chose to purchase a drone shortly after beginning my dealership because I wanted to be there for my customers,” said Titan. “I want to help farmers become more profitable by choosing the appropriate inputs for each unique situation.”

Titan has stayed ahead of the curve with regards to pairing his dealership with drones. He has found his drone to be especially useful when needing to scout during all seasons, because it’s not always convenient to walk through fields. He admits a drone will never replace recommendations from an agronomist or seed advisor, but it helps the farmer focus on problem areas.

Titan flies DJI models and is currently flies the Inspire 1. He says the customer service is great and they are fast and reliable when he needs parts. He advises not spending too much money on a drone because it’s just one tool in a farmer’s toolbox.

For more advice on how to fly your fields, click here.

Originally from Northeast Iowa, Logan Shedenhelm has found a new tool for his family’s farming operation that yields high results. The Shedenhelm’s could now scout their field in a timely manner, learning more than they ever have.

Originally from Northeast Iowa, Logan Shedenhelm has found a new tool for his family’s farming operation that yields high results. The Shedenhelm’s could now scout their field in a timely manner, learning more than they ever have.

“My summer internship with Latham Hi‑Tech Seeds helped me see the value of having an eye in the sky over our fields,” said Logan. “From making a sales pitch to improving our own operation, I have been able to uncover many things just from a different angle.”

This past summer, Logan flew the Phantom 4 and admits that this would be the model to invest in someday. Between the ease-of-use and high-quality camera image, Logan found this was a durable, all-in-one drone.

“Drone technology can be beneficial to a farming operation if used properly,” Logan said. “Drones can be used to see every single acre you farm or to view livestock in the pasture in a time-effective way.”

“Drone technology can be beneficial to a farming operation if used properly,” Logan said. “Drones can be used to see every single acre you farm or to view livestock in the pasture in a time-effective way.”

Logan found different uses for his drone from season to season. Starting with planting and early spring, he used the drone to look at emergence, stand and weather damage. In mid-season, he used the drone for weather damage, weed pressure and chemical injury. Coming closer to harvest, he was able to see where fields began to tassel or where disease pressure was taking over.

Early in the season after a rain, Logan flew the drone over a field back home in Riceville, Iowa. When taking the drone up, he was able to see the wet spots in between the tile lines. He discovered dry streaks in between the wet spots were the tile lines. After taking multiple pictures and videos, they have a good representation of where their tile lines were and were they needed to add more drainage.

Later in the season, it was easy to see compaction when flying the drone. Certain rows which look like there where from machinery, where shorter and lighter in color. These symptoms were from compaction.

“Drones can be a great investment and pay for themselves in just one year if used properly,” Logan said. “I was able to always find a reason to check fields no matter what the season. It is a benefit to see every field from a weekly basis instead of being blindsided by something that your drone could have seen when harvesting your crops.”

For more than a year, Ethan Johnson has operated a Phantom III Professional Quad Copter for Doug Abeln Seed Co. in Groton, South Dakota. He says the aerial images help them see trouble spots in fields.

For more than a year, Ethan Johnson has operated a Phantom III Professional Quad Copter for Doug Abeln Seed Co. in Groton, South Dakota. He says the aerial images help them see trouble spots in fields.

“We like to use the drone to help us with our tiling projects,” explains Ethan. “We look for trouble areas within a field that could be fixed with tile. We also like to use the drone to look at corn planter shut-offs in late spring to see if our planter is as accurate as the monitor says it is. The drone also has also been a helpful tool with crop insurance issues like spray damage or hail.

Unfortunately, this season he discovered a new use for their drone when Goss’s Wilt was spotted across a corn field. After seeing how badly the field was affected, Ethan says the next step is to select a hybrid with a better tolerance.

The view from a drone also allows farmers to see a different in stand between hybrids.

“Plant health is something we like to look at from above,” says Ethan. “It really gives you a different picture, literally, than what you can see at the ground level. You can see a lot from the air, at different times of the season. It’s helpful to identify problem areas before you’re in the combine.”

For farmers who are interested in purchasing a drone, Ethan recommends looking at the Phantom IV because it’s more up-to-date. He also advises them to consider purchasing the Sony

“Buy your drone as a package deal with extra batteries and a carrying case to save some money,” he says. “You will need an iPad Air II because older models won’t work. Finally, always be safe always. Use common sense when flying drones, so no one gets hurt.”

Rules require you to keep the drone in sight, and you must operate your drone at 400 feet or below. Click here for 5 things to know about the new FFA rules regarding UAVs (unmanned aerial vehicles, aka “drones”) for agricultural use.

By Joe Roberts, Latham Hi‑Tech Seeds Sales Intern

My dad decided to buy a drone because he believed it would help making better, more informed decisions on our farm.

My dad decided to buy a drone because he believed it would help making better, more informed decisions on our farm.

A drone can lead to better management practices in so many ways. When we have wet years and get in a hurry, sometimes we plant in conditions that aren’t ideal. Throughout the growing season, we can then fly the drone over those fields and see the impact of planting in wet conditions.

This summer, while I was flying drones as part of my internship with Latham Hi‑Tech Seeds, I could see compaction problems throughout the fields. You can identify problems like drown-out areas or high weed pressure areas. The same year you can go out and implement applications to correct that before the next growing season.

I believe seeing those areas through the lens of a drone during the growing season and then seeing yield differences on the monitor this fall will cause us to make changes next spring.

Flying a drone all summer long gave us the ability to “see the big picture” of an entire field. Sometimes problems occur in areas that aren’t visible from the ground or in places that aren’t easy to reach by walking a field. We were able to fly some fields that had to be assessed quickly for replant. In a few minutes, we were able to analyze every section of the field.

One of the coolest things I saw through the drone camera this summer was the progression of the stress wheel. Flying the drone over the crops as they developed held significance since I was able to help during planting. Flying over the Latham Seeds’ test plots and SuperStrips throughout the marketing area gave both farmers and myself an arial view of the differences in hybrids along with the progression of each one. Once you see some of the amazing pictures that a drone take, I don’t think you’ll ever look at your fields the same way!

Drones can be used at all points throughout the growing season, which really creates a good return on your investment. Early in the season, you can make notes about emergence or compaction  issues. When the crops emerge, you can fly fields to identify problems with fertilizer application and weed control. There’s always a use for a drone after a storm, whether you want to look for drowned-out spots or wind damage. Flying the drone makes quick work of all of these tasks, plus it’s a lot more fun! I’m looking forward to taking cool videos from planting to harvest, and then showing the photos to friends and family.

issues. When the crops emerge, you can fly fields to identify problems with fertilizer application and weed control. There’s always a use for a drone after a storm, whether you want to look for drowned-out spots or wind damage. Flying the drone makes quick work of all of these tasks, plus it’s a lot more fun! I’m looking forward to taking cool videos from planting to harvest, and then showing the photos to friends and family.

My advice to farmers is don’t let the fear of flying prevent you from getting a drone. The process to learn how to fly the drone can be accomplished in less than a day. It just takes some practice. There are even drones available with obstacle collision, so you don’t have to worry about crashing it anymore. Additional programs may be purchased to enhance the value of your drone. At the Farm Progress Show, I talked with a company representative that had mapping software for the drones, as well as the ability to spray fungicide over portions of your field.

As drones keep advancing, the sky’s the limit for the potential uses of your very own drone! Buying something that can have a practical use on the farm for more than one season looked to be a good investment, too.